Focus also on expert presentations, digital products, and industry services

The Vögele small MINI 500 road paver and the upgraded Ciber iNOVA 1200 asphalt mixing plant celebrated their market premiere at the Paving Expo 2025. At the joint Wirtgen Group and John Deere trade show booth in São Paulo, the group also presented a number of other competitive solutions for the industry.

Exhibits from Wirtgen, Hamm, and John Deere round off the machinery on show

Small-scale construction tasks like the capping of narrow trenches can now be completed quickly and efficiently. The new tracked paver from Vögele offers a high-quality solution to this challenge, with the MINI 500’s key features including an impressively compact footprint alongside various paving widths.

Despite its small size, the paver has a large material container featuring a broad, funnel-shaped opening that enables loading with a wheel loader or excavator. From a standing position at the paver, the operator has a clear view of the job in hand and can operate the MINI 500 easily.

Ciber’s proven iNOVA 1200 mobile asphalt mixing plant was on show for the first time, with a range of new features that improve control and efficiency in continuous asphalt production. Among the most important highlights is the new, dual-motor, twin-shaft external pugmill mixer with automatic fill level regulation. The filling level remains constant, enabling a high mixing quality even when there are fluctuations in the plant flow.

The new moisture sensors integrated into the aggregate containers permit a dynamic adjustment of the dosing based on the actual moisture level as measured. This reduces deviations in grain size distribution and improves the dosing of the asphaltic binder, which is an important step for continuous asphalt production. In addition, it also helps to reduce the costs per ton of material produced, especially in regions whose aggregates have naturally high levels of moisture or experience climatic fluctuations.

Ciber’s plant configurator shows how easy it is to put together an asphalt mixing plant to meet customer requirements. With its user-friendly interface and advanced functions for customization, the Configurator offered visitors to the Ciber booth an engaging and interactive experience.

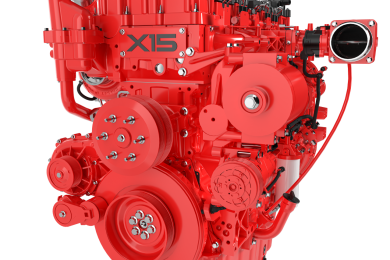

A Wirtgen milling machine and Hamm rollers round off the product range for intelligent and cost-effective road construction, with the 444 G wheel loader from John Deere for earthworks. Compared with its predecessor, the 444 G offers updates such as an improved power train as well as even quieter operation.

The redesigned cabin is now equipped with a new air-conditioning system plus an intuitive control panel, a 127 cm LCD monitor, and an integrated rearview camera. Other productivity enhancements include monitoring via the Connected Solutions Center (CSC), which enables remote diagnostics and early fault detection to improve the service life of machinery.

Wirtgen Group experts present talks on intelligent technologies

Presentations from industry experts were also very popular with trade show delegates. Vinicius Dutra Amann, Product and Application Specialist at Ciber, talked about how automated control systems and moisture sensors enable precise dosing of aggregates and binding agents during asphalt production, and how the efficient incorporation of RAP works to lower operating costs.

Vinicius Neukamp da Silva, Product and Application Specialist at Wirtgen Group, reported on road construction methods and new technologies that can improve the IRI (International Roughness Index), and therefore increase application efficiency while reducing costs.

High-quality asphalt installation with Vögele mobile feeders plus case studies from around the world were presented by Rafael Valentini, Senior Sales Manager Latin America/Europe at Vögele, whose presentation focused on improvements in workflow efficiency and the quality of asphalt pavements.

Digital solutions boost efficiency on the construction site

Another highlight at the booth was the John Deere Operations CenterTM. As the central platform for digital solutions from across the group, it enables the end-to-end management of construction sites, including planning, monitoring, maintenance, and analysis.

Also on show was the Ciber Plants Configurator – one of the most innovative attractions at the Paving Expo 2025. With its intuitive user interface and advanced customization functions, the Configurator gave visitors the chance to try out various combinations of the options, sensors, and dosing systems that are available with asphalt mixing plants from Ciber.

Underlining the company’s commitment to technology and operating efficiency, this tool simplifies the visualization of made-to-measure solutions for various application requirements and road construction projects.

Adriano Correia, CEO of Wirtgen Brazil: “The Paving Expo was a great success: we were able to take our customers through the machine solutions and technologies that enable high-quality, profitable project completion, and show how the Wirtgen Group and John Deere provide support for these projects as dependable partners.

This is all made possible by our highly integrated services, which also attracted a lot of interest from our Expo visitors.”

Partener Principal

MATEK Build Smart