Benninghoven – Austria’s First Asphalt Mixing Plant with Hot Gas Generator Technology as a Retrofit Solution

Maximized RAP Feed Rates, High Flexibility for Frequent Recipe Changes, and Minimal Emissions

In Vienna-Simmering, an established asphalt mixing plant was upgraded with a hot gas generator as a Retrofit solution. The retrofitting project was a premiere for Austria and the plant now stands out as the country’s most innovative asphalt production facility. The retrofitting of a hot gas generator using the counterflow principle means that the plant can now work with high RAP feed rates while simultaneously reducing its CO₂ footprint in the production of new asphalt mixes. Another benefit of this technology is the ability to maximize the proportion of RAP in all recipes. Thanks to the hot gas generator, the RAP material already achieves the end-product temperature of 160 °C, whereby high RAP feed rates are achievable despite frequently changing recipes.

Broad Spectrum of Recipes to Satisfy Customers’ Requests

Due to numerous requests for environmentally compatible construction materials on the part of customers, Austrian construction contractor PORR decided to upgrade their existing plant with the new recycling technology. At the site in Vienna-Simmering, some 30,000 tonnes of asphalt are produced with a variety of recipes every month. The contractor supplies the City of Vienna with mastic asphalt for track construction and hot-rolled asphalt, and offers a broad spectrum of recipes to meet the various requirements of its many customers. The high output of the plant underscores its economic viability.

Plans to Double the RAP Feed Rate

The objective of the first modernization phase was to double the RAP feed rate to 40%. “The volume of reclaimed asphalt we’ll be able to process with the new mixing plant will depend on how much RAP is available from road resurfacing projects,” explains PORR CEO Karl-Heinz Strauss. Also important is providing proof that the asphalt meets all standards in terms of metrics such as rut resistance and bearing capacity. The asphalt mix must naturally also meet the customers’ particular requirements.

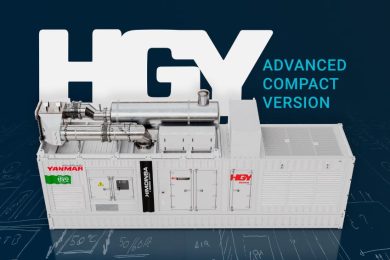

Retrofit Solution from Benninghoven

For Benninghoven, sustainability also means retrofitting rather than a new-build. The patented hot gas generator recycling technology enables asphalt mixing plant operators to produce asphalt mixes containing up to 100% of reclaimed asphalt – and that with minimal emissions. As a Retrofit solution, it can be integrated into existing plants. Before retrofitting, the specialists from Benninghoven get together with the customer to discuss and decide where and how which technology should be integrated. The basis of these discussions is a holistic consideration and analysis of the production process.

In Vienna, the retrofitting project was carried out in two construction phases to keep the downtime of the plant to a minimum. The first phase of construction involved the retrofitting of the cold recycling system. This was later followed by the erection of the structural steelwork, including the recycling drum, the hot gas generator, and the burner.

The Hot-Gas Generator Sets the Benchmark Standard for Recycling Technology

High RAP feed rates and simultaneously low emissions can be achieved only by the use of the counterflow principle in the hot gas generator. Here, the RAP material is indirectly heated to the optimum processing temperature of 160 °C and does not come into contact with the burner flame. “Generally speaking, we don’t need to pay attention to reducing emissions when we have high RAP feed rates.

The hot gas generator is a technology that completely avoids any emissions in the first place,” explains Steven Mac Nelly, Head of Development & Design Engineering at Benninghoven.

With the counterflow principle, burner fuel combustion takes place inside the hot gas generator and intensely heats the air circulating in the recycling drum. This hot air then acts as a material-friendly and indirect source of heat for the RAP material in the downstream recycling drum, heating it to the RAP material end-temperature of 160 °C.

This was the decisive factor for PORR, the operator of the plant in Austria. In Germany, for example, this ensures compliance with the TA-Luft regulations, and is enabled by Benninghoven in all output ranges of the hot gas generator.

Sustainability as a Part of the Closed-Loop Recycling Strategy

Benninghoven is not the only company focusing on sustainable solutions and cutting emissions. The plant operator is also focused on the achievement of a more sustainable business model. The use of hot gas generator technology is another milestone the company has passed on its way to the achievement a closed-loop recycling economy. In Austria, recycling materials are used as an alternative to primary resources wherever technically feasible and economically viable.

An Investment in the Future

The installation of hot gas generator technology contributes to the reduction of the CO₂ footprint. The use of 60% reclaimed asphalt when producing new asphalt mix can already cut CO₂ emissions in the overall road construction process chain by 20%. At the same time, this reduces asphalt production costs, because recycling material costs less than quarried virgin material. The Retrofit project has therefore paid off for the company in several ways, not only ecologically, economically, and through greater flexibility, but also with respect to the fulfillment of their customers’ requirements.

Partener Principal

MATEK Build Smart