From Swap Body Pioneer to Efficient Yard Logistics – TII KAMAG and Dachser: a Partnership of the Future

To mark the 30th anniversary of the KAMAG PrecisionMover (formerly known as the Wiesel), TII KAMAG is highlighting its long-standing collaboration with leading logistics company Dachser, the pioneer of the swap body. TII KAMAG was one of the first companies to manufacture the swap body transporter using series production thus

making an important contribution to increasing efficiency in the logistics sector.

With the introduction of the KAMAG PrecisionMover in 1995, TII KAMAG set a milestone for the logistics industry.

The PrecisionMover is a flexible and reliable swap body transporter that ensures maximum efficiency in yard operations. Dachser has been using the PrecisionMover for many years as an efficient solution for transporting swap bodies at various locations throughout Germany, thus supporting the high demands ever present in rapid goods handling. “As a pioneer of the swap body, we understand the importance of innovative transport solutions”, said André Bilz, Category Manager Truck, Trailer, Swap Body in the Corporate Indirect Procurement Division at Dachser. “We focus on holistic solutions that combine efficiency and future-proofing.

The KAMAG PrecisionMover perfectly meets this requirement and supports us in the daily challenges we face in handling operations.”

The invention of the swap body

In the 1970s, Dachser transformed the logistics industry with the introduction of the swap body. Thomas Simon, son-in-law of company founder Thomas Dachser, was inspired by the first US Army containers in German ports and adapted the concept for truck transportation. In 1971, Dachser introduced the first swap body – a load carrier that could be parked flexibly and swapped between vehicles. Fixed dimensions and foldout support legs are the

characteristic features of the swap body. This innovation reduces downtime and optimises freight handling thus significantly increasing efficiency levels across the entire transport sector.

Today, the swap body is one of the basic standards in the logistics sector and is essential for Dachser and many other companies.

Technological advancement: electromobility and autonomous systems

A significant step forward in the collaboration between TII KAMAG and Dachser is the deployment of the fully electric KAMAG ePrecisionMover which is already operational at the Dachser facilities in Hamburg and Erlensee.

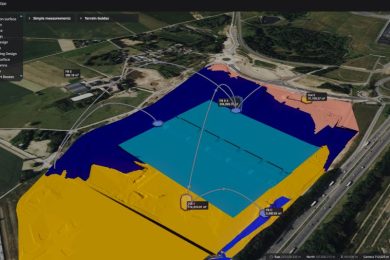

The low-noise, emission-free swap body transporter not only improves the environmental balance but also reduces noise pollution at the depots. “With the KAMAG ePrecisionMover, we are taking a decisive step towards combining sustainability and efficiency,” says André Bilz. Another example of the partnership’s innovative strength is the SAFE20 research project which was launched in 2020 and successfully completed in 2024. The aim of this project was to develop a safety concept for the use of autonomous vehicles in logistics yards. Through the collaboration of both companies, solutions were tested to enable the PrecisionMover to be controlled autonomously and safely at speeds of up to 20 km/h in depots.

The PrecisionMover today represents that which sets TII KAMAG apart: innovative strength, reliability and a clear vision for the future of logistics. “The needs and requirements of the logistics sector are evolving and we are evolving with them. For 30 years now, the KAMAG PrecisionMover has proven that it is a partner for the future. Our long-standing cooperation with Dachser shows how strong partnerships can shape the industry,”

explained Godehard Eidenhammer, Head of Sales Yard Logistics at TII KAMAG.

Company profile

The TII Group, a company owned by the Heilbronn-based Otto Rettenmaier family, is a globally active

manufacturer of heavyduty and special vehicles and has a workforce of around 1000 employees. The Group includes industry specialists, TII SCHEUERLE and TII KAMAG, and has production sites in Germany and India along with a worldwide organisation of sales and service partners. With innovative vehicles for manoeuvring and transportation operations, the TII Group, which is listed in the index of world market leaders, supports its customers in the

transport and logistics sectors, building industry, plant engineering, air and space travel, shipbuilding, energy, steel and mining as well as yard logistics for realising a wide range of complex transport tasks. The TII Group holds the current world record of over 23,000 tonnes for the transportation of extremely heavy loads on vehicles. TII stands for the tradition of innovation, customer orientation and partnership as well as for high product quality and

sustainability in heavy-duty mobility.

www.tii-group.com

Partener Principal

MATEK Build Smart